| This time, we want to introduce

a photovoltaic module manufacturing process we have learnt from

a training at Showa Solar Energy Corporation. Some details

of the processes which we were not taught in the training have

been ommited. |

Main Process Flow

9. Intermediate

Inspection

Make a visual inspection of

the junctions, and then measure the open-circuit voltage.

|

top top

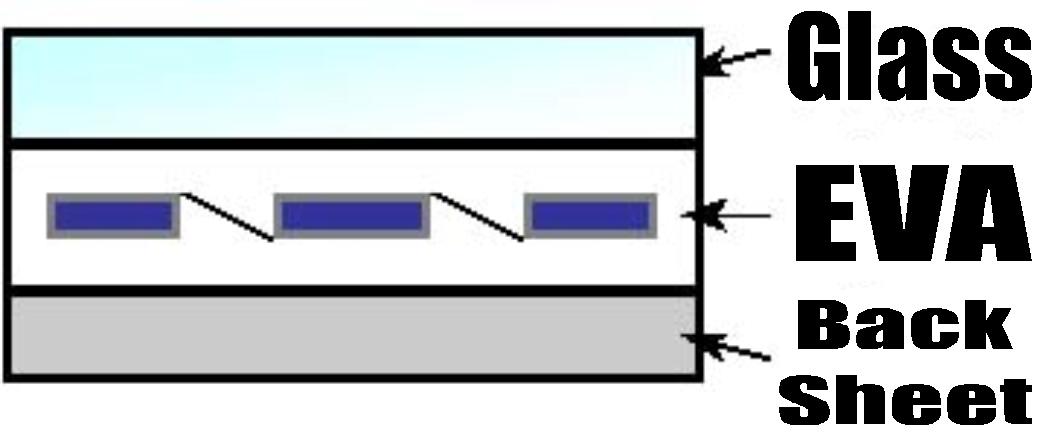

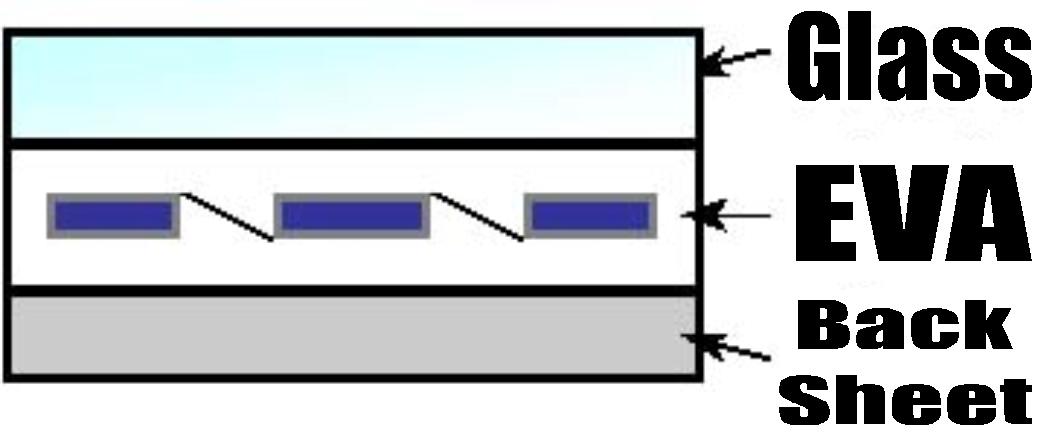

10. Laminating

EVA (Ethylene Vinyl Acetate)

is encapsulated between the solar cell and the tempered glass.

This module is heated in the laminating machine for one hour

so that the EVA is melted and cross-linked. After

this process, the structure of this module cannot be altered.

|

top top

11. Shaping

Cut off the extra back sheeting

and EVA with a hot knife.

|

top top

12. Edging

Double-faced tape with good

adhesion should be attached to the glass to make a frame.

|

top top

13. Framing

Compress the frame firmly.

Make sure that the double-faced tape adheres well. Once

the frame is attached, it can never be changed again.

After that, put bolts on it.

Compress the frame firmly.

Make sure that the double-faced tape adheres well. Once

the frame is attached, it can never be changed again.

After that, put bolts on it.

|

top top

14. Junction

Box

Make a hole on the back side

of the module so that the copper electrode is soldered and

connected to the copper wire. This junction is protected by

a junction box attached with silicon gum. The

silicon gum protects the module against humidity and water.

It takes two days to get dry completely.

Make a hole on the back side

of the module so that the copper electrode is soldered and

connected to the copper wire. This junction is protected by

a junction box attached with silicon gum. The

silicon gum protects the module against humidity and water.

It takes two days to get dry completely.

|

top top

15. Final

Inspection

Characteristics of the photovoltaic

module are checked by a solar simulator instantaneously. I-V

(current-voltage) characteristic is measured using a simulator

flash. Also the junction, any change in color, and bubbles

inside of the EVA should be checked for visually.

|

top top

previous

next next

|